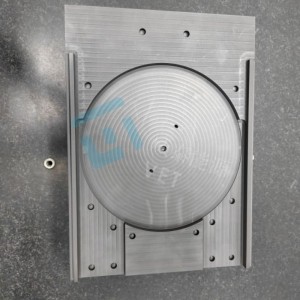

SiC Coated Graphite Halfmoon Part is a key component used in semiconductor manufacturing processes, especially for SiC epitaxial equipment. We use our patented technology to make the halfmoon part with extremely high purity, good coating uniformity and an excellent service life, as well as high chemical resistance and thermal stability properties.

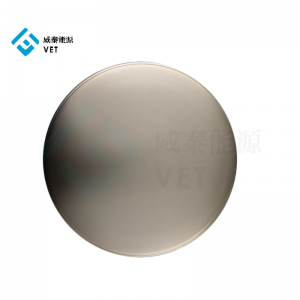

Base material: high-purity graphite

Purity requirements: carbon content ≥99.99%, ash content ≤5ppm, to ensure that no impurities are precipitated to contaminate the epitaxial layer at high temperatures.

Performance advantages:

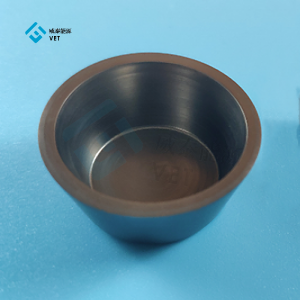

High thermal conductivity: The thermal conductivity at room temperature reaches 150W/(m・K), which is close to the level of copper and can quickly transfer heat.

Low expansion coefficient: 5×10-6/℃ (25-1000℃), matching the silicon carbide substrate (4.2×10-6/℃), reducing the cracking of the coating caused by thermal stress.

Processing accuracy: A dimensional tolerance of ±0.05mm is achieved through CNC machining to ensure the sealing of the chamber.

Differentiated applications of CVD SiC and CVD TaC

|

Coating |

Process |

Comparison |

Typical application |

| CVD-SiC | Temperaute: 1000-1200℃Pressure: 10-100 Torr | Hardness HV2500, thickness 50-100um, excellent oxidation resistance (stable below 1600℃) | Universal epitaxial furnaces, suitable for conventional atmospheres such as hydrogen and silane |

| CVD-TaC | Temperature: 1600-1800℃Pressure: 1-10 Torr | Hardness HV3000, thickness 20-50um, extremely corrosion-resistant (can withstand corrosive gases such as HCl, NH₃, etc.) | Highly corrosive environments (such as GaN epitaxy and etching equipment), or special processes requiring ultra-high temperatures of 2600°C |

Quality inspection

Coating thickness: laser thickness gauge (accuracy ±1um) or SEM cross-sectional analysis.

Bond strength: scratch test (critical load > 50N) or ultrasonic testing (sound velocity > 5000m/s).

Corrosion resistance: mass loss rate (<0.1 mg/cm²・h) tested in HCl atmosphere (5 vol%, 1600℃).

VET Energy is a professional manufacturer focusing on the R&D and production of high-end advanced materials such as graphite, silicon carbide, quartz, as well as the material treatment like SiC coating, TaC coating, glassy carbon coating, pyrolytic carbon coating, etc. The products are widely used in photovoltaic, semiconductor, new energy, metallurgy,etc..

Our technical team comes from top domestic research institutions, can provide more professional material solutions for you.

VET Energy advantages includes:

• Own factory and professional laboratory;

• Industry-leading purity levels and quality;

• Competive price & Fast delivery time;

• Multiple industry partnerships worldwide;

We welcome you to vist our factory and laboratory at any time!